Cross Dock Warehouse – An Ultimate Guide

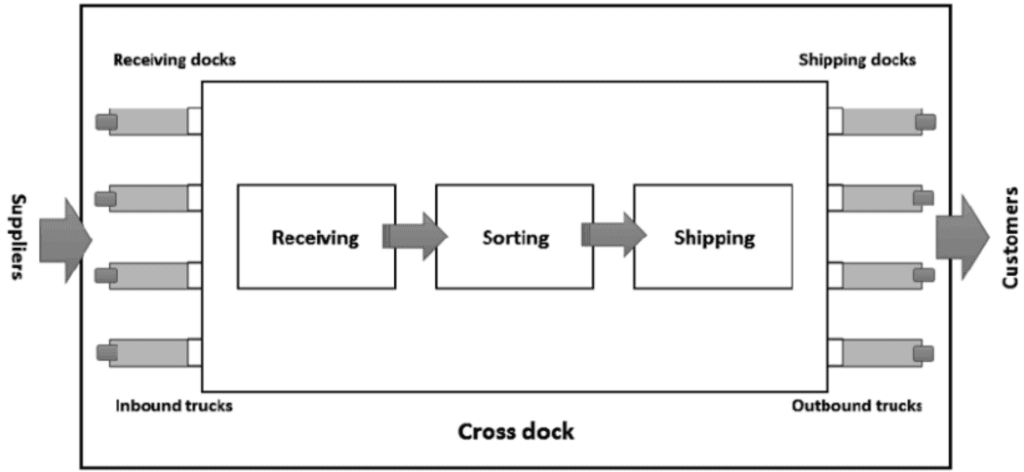

Cross-dock warehouses are an expedited avenue for fulfillment. It is a type of warehouse that receives goods from inbound vehicles, sorts the goods, and loads them onto outbound vehicles for delivery. There is limited holding or storage of goods in cross-dock warehouses, resulting in faster fulfillment. This type of warehouse is advantageous as it improves the efficiency of supply chain management, reduce inventory holding cost, and improve fulfillment speed.

Keep on reading as this post will reveal detailed information about cross-dock warehouses.

Key Features and Functions of Cross-Dock Warehouses

Cross-dock warehouses have played a significant part in the speedy distribution of goods over the years. This has been possible due to its features, which outrightly influence the functions it provides. These key features include:

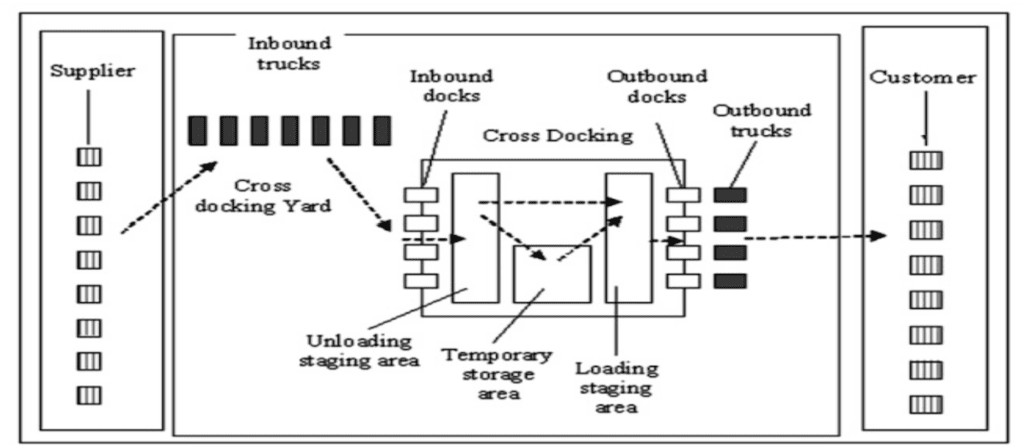

- Docking and staging areas: There are several docks to accommodate incoming and outgoing vehicles. These docks aid in the seamless transfer of goods from incoming vehicles to outgoing vehicles.

- Minimal inventory holding time: Cross-dock warehouse eliminates storage requirements as goods are transferred to outbound vehicles as fast as possible. As a result, goods spend less time in the warehouse.

- Efficient material handling equipment: Sophisticated equipment to ease the transfer of goods between vehicles is always available. This equipment includes conveyor belts, forklifts, pallet jacks, etc.

- Strategic location: Cross-dock warehouses are located in areas of close proximity to transportation hubs. As a result, suppliers and customers have easy access to the facility.

Operational Workflow of Cross-Dock Warehouses

This is a run-through of all that happens in a cross-dock warehouse, beginning from the first activity to the last. The functions of the cross-dock warehouse are seen via this workflow.

Receiving and Sorting

Receiving

The goods arrive at the warehouse via the inbound vehicles. Then the following actions are taken:

- The goods are checked in line with the papers and documentation for accuracy.

- The goods are unloaded from the inbound vehicle and assigned tracking numbers.

- Further checks are carried out on the goods for damage and quality control.

Sorting

This involves arranging goods based on outlined criteria such as type, destination, delivery time frame, etc. Upon receiving the goods, the next step is to sort, categorize and segregate the goods based on the criteria mentioned above. Though it can also be done manually, the sorting process can be automated with the use of Radio Frequency Identification technology or barcodes to speed up the process.

Receiving and Sorting

Consolidation happens when shipments from individual shippers arrive at the warehouse and these shippers want consolidation service in transporting the goods to their next destination. Consolidation is common for goods heading to the same destination or customers. In this case, the goods are combined and loaded onto the outbound vehicle for further shipping.

On the other hand, deconsolidation happens when consolidated shipments arrive at the cross-dock warehouse but need to be transported to different destinations or customers. The shipments are unloaded from the inbound vehicle, checked, and transferred to the consolidation area. In the deconsolidation area, the shipments are sorted and broken down into separate or smaller shipments before loading onto the outbound vehicles.

Order Fulfillment and Outbound Shipping

Following the chain, this is the last phase of the workflow. Shipments are arranged based on the destination, customer, and delivery time. Then they are loaded onto the appropriate outbound vehicles, which take them out of the warehouse to the next destination.

Types of Cross-Dock Operation?

There are different cross-dock operations to meet the dynamic logistics needs of different businesses, including

Pre-Distribution Cross Docking

This involves receiving, sorting, loading, and shipping to predetermined customers. The customer information is sent to the warehouse before the shipment leaves the supplier. Here is a quick rundown of the process.

- Receiving goods

- Sorting

- Product inspection and labeling

- Loading and transportation

Pre-distribution cross-docking is suited for the following situations:

- Quick response to demand: When there is no clear demand pattern, pre-distribution cross-docking can help respond to fluctuating demand.

- New product launch: Pre-distribution aids market penetration as goods can be rapidly sorted and shipped to distribution centers, stores, etc.

- Just-in-time delivery: Pre-distribution cross shocking is an ideal choice for businesses that want to deliver goods just in time. Goods are prepared for delivery immediately after it arrives at the cross-dock warehouse

Pre-distribution cross docking provides the following benefits:

- It reduces delivery time as goods are quickly cross-docked and ready for delivery.

- It provides a way to minimize inventory holding costs.

- It simplifies and improves supply chain efficiency by eliminating unnecessary handling and reducing transportation distance.

- There is flexibility and improved responsiveness to the changing consumer needs.

Post-Distribution Cross-Docking

As the name suggests, it is a cross-docking operation that happens after the original distribution of goods to their destination. It is also a system where goods are delayed until the customers are identified. Post-distribution cross docking gives more time for informed decisions, resulting in the storage of goods for a short time.

Post-distribution cross-docking is used when there is no clear path for the product journey. It is also used when there is a need for an adjustment of the regional market. The advantage of post-distribution cross docking is that it gives time for efficient planning. As a result, the next phases of the journey can be optimized.

Opportunistic Cross-Docking

This type of cross-docking operation takes advantage of opportunities that arise. Let’s have a look at some opportunistic situations that will help explain this operation better.

- Fluctuating Demand: When there is a sudden rise in demand in a region, suppliers tend to seize the opportunity for making extra sales by cross-docking goods and sending them to those areas.

- Excess Transportation Capacity: In times when there is excess capacity, additional goods can be cross-docked and used to fill up the spaces.

Opportunistic cross-docking provides increased flexibility as businesses can seize opportunities for profits. It also improves the utilization of resources.

Design and Layout Consideration

The design of a cross-dock warehouse is a significant contributor to its efficiency. Its design and layout are different from other regular warehouses. An efficient cross-dock warehouse is a product of the principles and considerations outlined below.

- The layout must support the seamless flow of goods from inbound docks to outbound docks. This should be void of obstacles and long distances.

- The dock configuration should depend on the type and volume of goods that will be handled in the warehouse.

- There should be separate areas for unloading and sorting incoming goods. The same should happen with outgoing goods as there should be a special area for consolidation and loading.

- Consider and set measures to ensure smooth traffic flow. Trucks should have good space for movement to avoid congestion.

- There should be a space for short-term storage as it is not a priority for cross-dock warehouses.

- There should be clear floor markings and signage.

- Proper lighting, ventilation, emergency exits, and other safety measures must be incorporated.

Dock Configuration and Equipment

There are several dock configurations, with each meeting different needs. Here is a rundown of the highly efficient dock configurations:

- Straight dock: This is the most basic as it is used when there is limited space and there is a requirement for a straightforward flow of goods.

- L-shaped dock: This is formed by perpendicularly connecting two docks. It provides more loading and unloading points and is crucial for a high volume of goods.

- T-shaped dock: This dock assumes a T-shape, which can accommodate several trucks simultaneously.

- U-shaped dock: There is increased flexibility and capacity with this dock configuration. It consists of a main dock area having dock doors on three sides.

There are several pieces of equipment used to design the docks in the different configurations as explained above. These pieces of equipment are vital as they fulfill different purposes.

- Dock Seals and Shelter: These are used to enclose a trailer opening. When the trailer is docked, the seal creates protection around the trailer to prevent external elements such as dirt, pest, etc.

- Dock levelers: It is used to level the height between the bed of a truck and the loading dock. This will aid in the easy movement of handling equipment between the truck and the dock.

- Vehicle restraint: This will work at the rear of the trailer to prevent separation of the trailer from the dock during operations.

- Dock lights: These are lighting fixtures to provide illumination and ensure visibility during operation on the dock.

- Dock bumpers: These bumpers provide a cushion as vehicles move on the dock. This will help to keep the dock’s integrity.

- Dock fan: Provides ventilation in the dock area.

Storage and Inventory Management

Although there is limited storage time with cross-dock warehouses, it is out of place for it to exist without proper storage and inventory management system. Here are strategies that can prove to be effective.

- Classification of goods: This should be done on the bases of delivery time, destination, and type. This will help provide a clear demarcation and easy identification.

- Employ technology: A good example is the use of bar codes, which will provide details on the location and description of each good. Other inventory management software will help keep track of inventory levels.

- Employ safety measures: Safety protocols are vital for storage and inventory management. This includes compliance with safety standards, the use of safety facilities like CCTV cameras, etc.

Types of Cross-Dock Operation?

Managing every operation in a cross-dock warehouse is challenging. However, technology has made warehousing easier by automating several processes. This includes the integration of systems and software such as Warehouse Management Systems, Automated Conveyor Systems, etc.

Warehouse Management Systems

The implementation of Warehouse Management System has streamlined processes and improved the overall efficiency of cross-docking operations. Here are the ways this system has contributed to cross-dock warehousing:

- It improves workflow management as it automates processes such as sorting and classification. With these systems, every operation is documented into one mix for easier scrutiny and management.

- It enables automated inventory tracking, as one can know the state of inventory in a few clicks.

- It provides real-time visibility on every cross-docking operation.

- It enables seamless integration with other supply chain software for easy data sharing and collaboration.

Automated Sorting and Conveyor System

Sorting goods is inevitable but tedious. The application of automated sorting and conveyor system has made it stress-free and more efficient. The conveyor system has a sorting mechanism controlled by software. The software algorithm dictates the sorting criteria and the conveyors move to do the job.

With this system, there is less human labor, which will save cost, and enhance efficiency and accuracy.

Real-time Tracking and Visibility

The importance of real-time teaching and visibility in modern-day logistics can not be over-emphasized. It plays a vital role and has provided solutions to several problems encountered in previous eras.

- It provides enhanced visibility as the management can see the movement of goods as it goes through the cross-docking process.

- It helps monitor and evaluate resources. As a result, areas needing more attention can easily be identified.

- There is improved order fulfillment as managers can track orders and ensure timely delivery.

- It helps spot areas of lapses or issues quickly.

- Through real-time data, management can make good decisions and effective plans.

- It streamlines the process resulting in prompt delivery. This will also lead to customer satisfaction.

Benefits and Use Cases of Cross-Dock Warehouses

Just-in-time Inventory Management

With cross-docking warehouses, goods can be received and processed as they are needed by customers – this is the concept of just-in-time-inventory management. It is all about having the right quantity of goods at the right time, not keeping them in excess. Cross-docking is an expedited process that will keep goods for a short time and send them out immediately after they are ordered.

Reduced Inventory Holding Cost

Regular warehouses tend to hold goods for a long time and they charge for the goods according to the time they have spent in the warehouse. However, with cross-docking, the storage time has been significantly reduced since goods are sent out quickly. The less the storage time, the less cost of holding inventory.

Improved Order Fulfillment Speed

Cross-dock warehouses are designed to operate a fast-paced model. Goods are received by inbound vehicles, they are sorted and packaged, then they are loaded onto outbound vehicles for delivery. The cross-dock systems give little or no time for holding inventory, hence fulfillment becomes faster.

How Al Sharqi Can Help

Al Sharqi Shipping offers reliable services in well-equipped and sophisticated cross-dock warehouses. We provide cross-dock services aided by advanced technology. We guarantee

- Improved fulfillment speed

- Enhanced supply chain efficiency

- Real-time tracking and visibility

- Streamlined processes

- Clear and consistent communication

- Safety and Security

- Customer satisfaction

Reach out to us for more information.

Conclusion

Cross-dock warehouses have stepped in to provide faster fulfillment and less holding of inventory. This is possible since cross-docking involves receiving, sorting, and loading goods onto outbound vehicles for delivery. Its design and layout are well thought out as explained in this post. Technology is a mainstay in cross-dock warehouses, hence equipping it to optimize supply chain operations. It is a good decision to embrace cross-dock warehouses for improved supply chain efficiency.

Frequently Asked Questions

A cross-dock warehouse is a type of warehouse that receives goods, sort them immediately, and loads them onto outbound vehicles for onward shipment. Goods are not stored for extensive periods.

Cross-dock warehouses expedite the fulfillment and shipment of goods compared to traditional warehouses. Traditional warehouses will store goods for longer periods while cross-dock warehouses store for little or no time.

Following are some of the benefits of using cross-dock warehouses:

- Improved fulfillment efficiency.

- Lower inventory holding cost as there is little time for storage.

- Faster fulfillment as goods are sorted and shipped rapidly.

- Improved inventory control and management as it ensures that the right quantity of goods is available at the right time.

- Improved visibility and supply chain efficiency.

Cross-docking offers a system that minimizes the holding or storage of inventory. This controls the number of goods and prevents wastage or excess. It matches the idea of having the right quantity of goods at the right time.

Cross-docking does not hold goods for long. It receives goods, sorts and makes them available for delivery as fast as possible.

Our customer service team is happy to assist you with planing your next booking.

Related Articles

Optimize Warehousing, Fulfillment and Shipping Cost

In today’s fast-paced business environment, efficient distribution and shipping play a crucial

Frozen and Chilled Storage Warehouse in Dubai

Dubai’s hot climate means efficient storage is a prominent concern for manufacturers and selle

Keeping Your Food Safe with Food Grade Warehouse in Dubai

Currently, the United Arab Emirates (UAE) relies on other countries for the bulk of its food supplie

Post a comment

You must be logged in to post a comment.